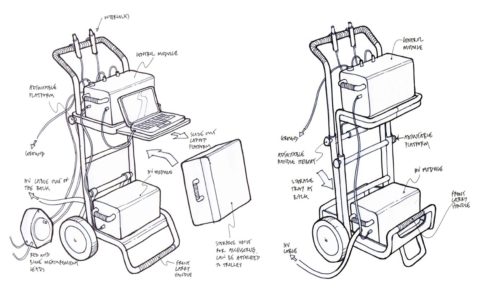

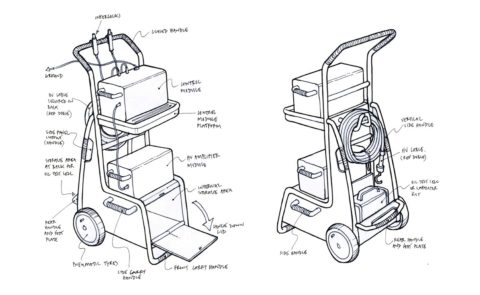

Delta 4000 electrical tester development

Megger Delta 4000 fully automatic 12 kV insulation power factor / dissipation factor test set was developed by Gm Design Development in collaboration with Sadler Associates. The product was designed for condition assessment of electrical insulation in high voltage apparatus such as transformers, bushings, circuit breakers, cables, lightning arresters, and rotating machinery. We developed both the control unit as well as a trolley/ stand used to transport the system from the van to the site for the tests to be carried out. We developed the design from concept through to detailed 3D CAD.

A complete modular system was developed as part of a trolley based tester allowing it to be portable, for use in the field or in-shop.

The challenge

The complete unit had to be low weight and a compact size that was better than the competition.

The construction was a key factor in a product such as this where numbers are relatively low for injection moulding and is a large device. The use of fabricated sheet metal combined with moulded corner detailing provided a modern looking device that could still be manufactured at a viable cost. This also allow the Megger brand to come through in the construction of each unit.

The outcome

The bespoke trolley was developed as a series of tubes, combined with some fabricated sheet material. The units could either be transported to the test site using the trolley, or each unit could be unplugged and carried separately and then stacked. Handles were integrated into each unit allowing individual units to be easily carried.