There are a number of TPEs that have passed cytotoxicity tests (ISO 10993-5) and biocompatibility tests (USP Class VI). The materials are latex free, reducing the risk of allergic reactions. They are available in a range of shore hardness’s from shore A to 65 shore D. Transparent grades are available, as well as grades suitable for two-shot moulding to engineering thermoplastics. We are currently using these in a number of products we are developing. If you have a project where the use of TPE would be advantageous, then please feel free to contact us for further advice.

Designing medical devices – London & UK

Gm Design Development is experienced in designing medical devices – both diagnostic and surgical applications. We use 3D CAD to design in detail and fully engineer the components to deliver innovative medical devices. Creo and SolidWorks are our preferred CAD software. To deliver a successfully device, there are many factors that go into the design. […]

3D CAD services for London & UK

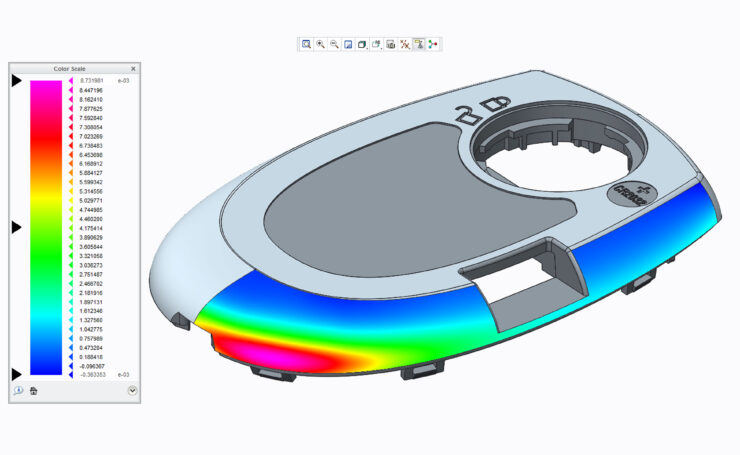

As an industrial designer, I have been using 3D CAD to develop designs and fully engineer products for manufacture. Creo and SolidWorks are my preferred CAD software.At Gm design Development, we undertake all aspects of product design, from concept generation to production and we use 3D CAD extensively.Key area we are experts in are: Advanced […]

Underestimating the design for manufacture activities within your product development can lead to costly tooling modifications and additional time required to correct the problems. Some of the common mistakes that are made include: Failure to take account of these important aspects early in the design process can lead to increased time and costs and a […]

Virtual hospital wards

Advances in technology allowing for medical treatment in the home is already delivering huge savings for the NHS by allowing the strategy of ‘virtual hospital wards’.The Medway NHS Foundation trust is using an infusion pump produced by Vygon UK to allow patients to remain in their own home. The patients’ vital signs are remotely monitored […]

Monitoring our own health

Monitoring our own health and diagnosing conditions are becoming more common and will become increasingly necessary in the management of our health. Various diagnostic tests can now be performed in our home. Common types are typically saliva and blood tests.If performed correctly, many tests deliver accurate results, however the majority are less than ideal from […]

We are featured in the November edition of the Surrey Chamber of Commerce magazine. An article on our collaboration with Martindale Electric Ltd, designing their new Proving unit electrical safety product. CLICK HERE (Page 11).

We appear in this months (June edition) Surrey Chamber of Commerce magazine. A short article on our collaboration with Invitron, designing their rapid diagnostic test to detect if somebody has had a heart attack. (Page 13).

Gm Design Development collaborated in the development of a revolutionary portable device that can perform rapid high-sensitivity medical diagnostic tests that would normally need to be sent to a laboratory for analysis. GmDD was commissioned by Invitron www.invitron.com , a UK based biotechnology company, to help with the design, development and engineering of the new […]

Gm Design Development completed the redesign of the CABLOK device for Martindale Electric. The device is used during maintenance as part of a safe isolation procedure. It can accommodate 6 padlocks for use by multiple operators working at the same time. This is the second product we have designed for the company. Working with the […]

Designing rapid diagnostic products

We are featured in this months Surrey Chamber of commerce magazine. Page 72. You can read the digital copy by clicking the following link CLICK HERE:

At Gm Design Development, we work with local Surrey-based businesses to design and engineer their new products. We use 3D CAD extensively, using packages such as PTC Creo to develop their technically challenging products for manufacture. Our design studio based in Surbiton, Surrey is only a 10-minute drive up the A3 from Junction 10 inside […]

At Gm Design Development, we work with many London based businesses to design and engineer their new products for them. Our Greater London design studio is only a 20-minute train journey from London Waterloo, inside the M25 by car. As well as established London-based businesses, we work with start-up businesses based at the Imperial College […]